Exploring Ceramic Injection Molding: A Revolutionary Manufacturing Process

Ceramic injection molding (CIM) is a cutting-edge manufacturing process that merges the flexibility and precision of plastic injection molding with the strength and durability of ceramic materials. This process has quickly become a game-changer across industries like aerospace, medical devices, automotive, and electronics. With CIM, manufacturers can create highly complex parts with tight tolerances and superior material properties, resulting in long-lasting parts with minimal maintenance needs. By combining ceramic powders with binders, the process offers a unique way to produce intricate, durable components that would be challenging or impossible to make with traditional ceramic forming methods. Whether you’re new to the world of CIM or looking to understand its vast potential, this article will provide you with a comprehensive overview of how it works and its many benefits.

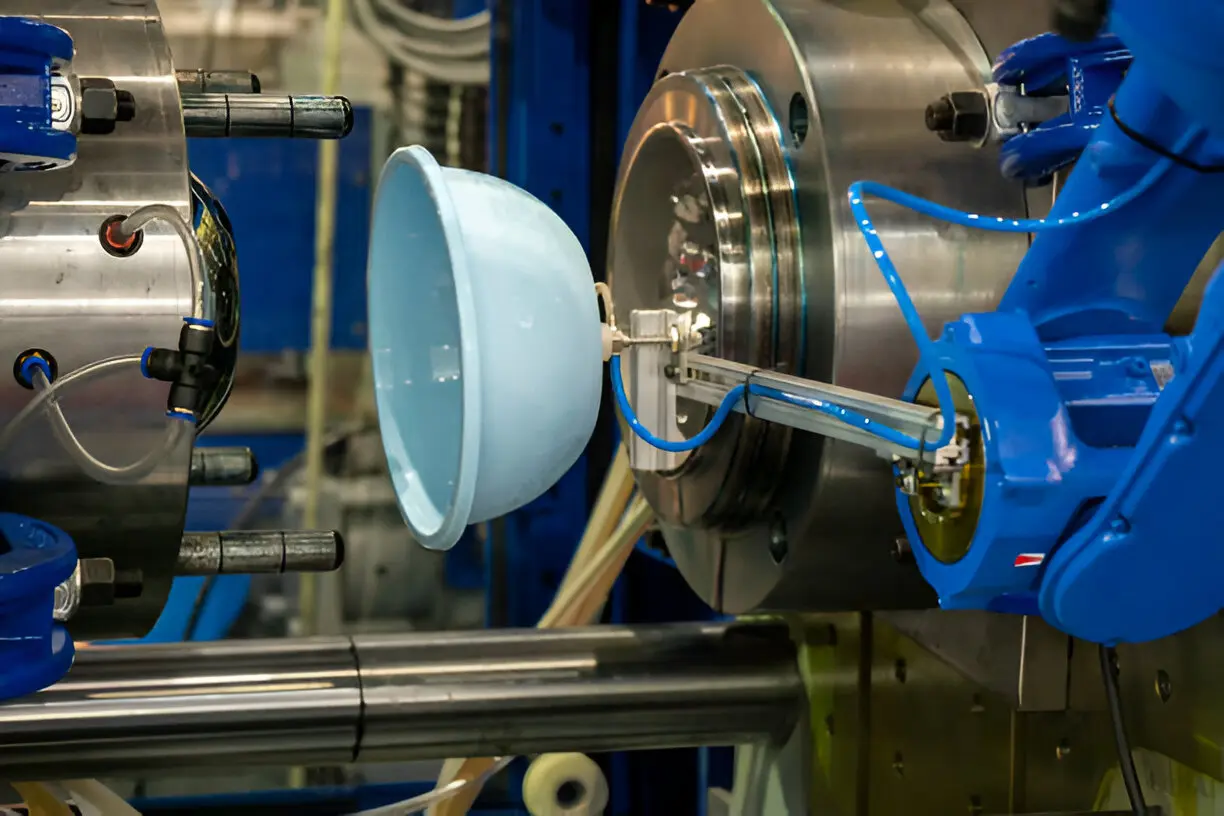

The Basics of Ceramic Injection Molding

At its core, ceramic injection molding is a specialized technique used to manufacture high-performance ceramic parts. The process begins by mixing ceramic powder, typically alumina or zirconia, with a binder to form a feedstock material. This feedstock is then injected into a mold under high pressure, similar to plastic injection molding. The result is a “green” part, which contains a mixture of ceramic and binder materials.

Once the part is molded, it undergoes a debinding process, where the binder is removed, and the part is left with a framework of pure ceramic material. The final step is sintering, where the part is heated to a high temperature, allowing the ceramic particles to fuse together, increasing its strength and durability. After sintering, the part is ready for use in high-demand applications.

Why Choose Ceramic Injection Molding

Ceramic injection molding stands out for its ability to produce highly complex geometries that would be difficult to achieve using other methods like traditional ceramic casting. The process is incredibly versatile, allowing manufacturers to design parts with intricate details that can meet precise specifications.

1. Precision and Accuracy

One of the most significant advantages of ceramic injection molding is its precision. The high-pressure injection of the ceramic feedstock ensures that even the smallest details are captured with incredible accuracy. Parts produced using CIM often have tighter tolerances than those made with traditional manufacturing methods, which is critical in industries that demand high-quality, high-performance components.

2. Cost-Effectiveness

While ceramic materials are often associated with high costs, ceramic injection molding can be more affordable than alternative manufacturing processes for certain applications. The ability to produce parts with minimal material waste and reduced labor costs helps make CIM a cost-effective solution for both low and high-volume production runs.

3. Complex Part Geometries

CIM is particularly well-suited for producing parts with complex shapes that would otherwise require extensive post-processing or assembly. For example, intricate lattice structures or internal channels can be molded directly into the part, eliminating the need for additional steps and improving the part’s overall strength.

Applications of Ceramic Injection Molding

Ceramic injection molding is used in various industries, and its benefits are felt in each sector. The aerospace industry, for instance, uses CIM to produce high-performance components that need to withstand extreme temperatures and pressure. Similarly, the medical device industry uses CIM to manufacture surgical instruments, implants, and diagnostic equipment that require both precision and durability.

- Medical Devices: Parts such as surgical tools and implants benefit from CIM’s ability to produce highly intricate designs with exceptional durability.

- Aerospace: CIM is used to create lightweight yet robust components for aircraft engines and other critical aerospace applications.

- Electronics: Many electronic components, such as connectors and insulators, are produced using CIM due to the material’s excellent electrical insulation properties.

- Automotive: Automotive manufacturers use ceramic parts for engine components, sensors, and other critical components that require high wear resistance.

Benefits of Ceramic Injection Molding

As industries evolve and demand for precision and performance increases, ceramic injection molding continues to meet these needs with unparalleled efficiency and flexibility. The process’s ability to produce high-quality, durable parts at a lower cost has cemented its place in modern manufacturing.

1. Efficiency

Because CIM allows for the production of complex parts in a single process, manufacturers save time and reduce costs associated with multiple steps. Additionally, the automation of the injection molding process results in more efficient production, reducing the overall time it takes to create a part.

2. Material Versatility

Ceramic injection molding is compatible with a wide variety of ceramic materials, including zirconia, alumina, and others. These materials are known for their strength, wear resistance, and electrical insulation properties, making them ideal for demanding industries like aerospace and electronics.

3. Sustainability

The ability to minimize material waste is another key advantage of CIM. The process is highly material-efficient, which not only reduces costs but also makes it a more sustainable option for manufacturers.

The Role of Legal Experts in Manufacturing Processes

While discussing advanced manufacturing technologies like ceramic injection molding, it’s also important to recognize the legal side of the industry. In industries with high precision, such as ceramics or aerospace, workers often deal with specialized tasks that come with an inherent risk of injury. Workers’ compensation lawyers play a crucial role in ensuring that employees in these industries are protected in the event of an accident. If you’re seeking help navigating these challenges, you can visit California Workers Compensation Lawyers.

These legal experts help workers navigate complex workers’ compensation claims and advocate for their rights if they’re injured on the job. Whether dealing with repetitive strain injuries from long hours at machines or injuries from heavy machinery, workers’ compensation lawyers are integral in securing financial support and medical benefits for employees.

With the fast pace of technological advancements in manufacturing, it’s essential for both employers and employees to be aware of their rights and responsibilities. Workers’ compensation lawyers help safeguard the interests of workers, ensuring that they receive fair treatment and compensation for work-related injuries, ultimately contributing to a safer and more efficient work environment.

Ceramic injection molding is an innovative and versatile manufacturing process that has transformed industries worldwide. With its ability to create intricate, high-quality parts with unmatched precision, CIM is poised to continue driving advancements in fields ranging from aerospace to medical devices. As industries evolve and demand for better performance grows, ceramic injection molding will remain a critical player in the future of manufacturing.

By understanding the unique benefits and applications of CIM, companies can stay ahead of the curve, ensuring they remain competitive in the ever-changing manufacturing landscape. As technological and legal frameworks continue to adapt, processes like CIM will only become more refined, offering exciting opportunities for innovation in the years to come.

Also Read-How Drone Technology Enhances Construction Site Monitoring